Understanding Backflow

The holidays are joyful, but all the extra hustle and bustle can make them stressful. People stay so busy this time of year that a single problem can derail their entire agenda for days. Plumbing is notorious for waiting until busy times to fail, which can be true for backflow preventers.

Backflow prevention is already a problem that most people don’t understand. Compounding with the stress of the holidays, this can wreck the entire season. Instead of taking the risk, be proactive. Here is a quick guide explaining backflow, how it is prevented, and why prevention is necessary.

Risks of Backflow

Backflow occurs anytime water flows backward through piping, such as during pipe bursts or periods of heavy consumption. While this may seem innocuous, the real threat is what is caused during backflow.

Backflow occurs anytime water flows backward through piping, such as during pipe bursts or periods of heavy consumption. While this may seem innocuous, the real threat is what is caused during backflow.

When backflow occurs, negative pressure builds up in the pipes, leading to siphoning from any open point of use in the plumbing system. The siphon caused by backflow can pull things into pipework like:

- Air

- Contaminated groundwater

- Sewage

- Chemicals

- Fertilizers

- Wastewater

Freshwater piping is specially designed to ensure nothing enters the systems. When anything other than freshwater flows through the piping, it becomes contaminated and can cause problems corresponding to whatever entered the piping.

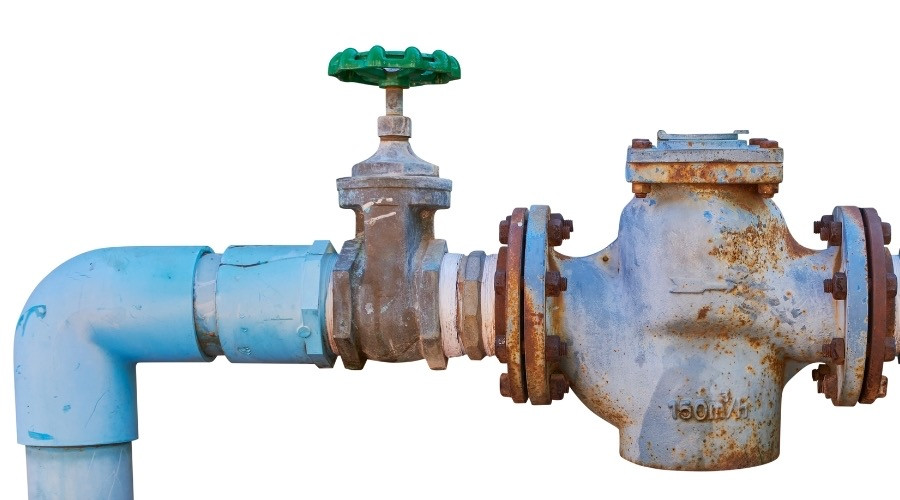

Luckily, backflow is prevented in most cases by a series of devices called backflow preventers located on the water grid and within the properties of residential and commercial water customers.

What Is Backflow Testing?

Backflow testing is the process by which plumbers check backflow prevention devices for proper operation. Where are these devices? Most backflow preventers are located in industrial or commercial places where customers use lots of water and produce some of the harmful compounds listed above.

Backflow testing is the process by which plumbers check backflow prevention devices for proper operation. Where are these devices? Most backflow preventers are located in industrial or commercial places where customers use lots of water and produce some of the harmful compounds listed above.

Additionally, many backflow preventers are installed and maintained by the municipality to protect the water grid. In homes, most backflow prevention is handled by using air gaps according to code.

Air gaps do not have to be tested but must be inspected by local code management professionals to ensure they are in place. If backflow preventers are in place around a residential property, they are most likely a part of the irrigation system.

Building codes mandate that backflow preventers be inspected and certified annually or upon a backflow event. Local enforcement will require the owners to produce documentation to prove the inspections are up to date. Luckily, this process is quick and easy when done by specially-trained plumbers.

Why is Backflow Testing Necessary?

Backflow prevention is one of the keystones of public health. Indeed, good public health can only exist with easy access to safe water for drinking and cleaning. If backflow were left unchecked, the consequences could impact entire cities.

When backflow preventers fail, citizens are exposed to human and biohazardous waste, dangerous chemicals, and harmful pathogens. The only option is to purge the system, which has, in some documented cases, required the loss of millions of gallons of treated water to remove the harmful contaminants.

About Bud's Plumbing & Repair Service

Bud's Plumbing & Repair Service helps protect water supplies with the highest levels of professionalism for plumbing installations and backflow testing. They offer fast service and take pride in communicating with their customers as they make repairs. Call today for backflow testing and certification service in Evansville, IN.